Abstract

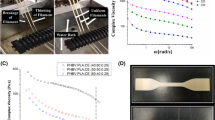

Polylactic acid (PLA) is a biodegradable and bioresorbable biopolymer that has successfully been applied in biomedical and related fields. It is in the form of filaments, presenting different colors, with the purpose to be used in the three-dimensional printing (3D) technique. Thus, this work aimed to characterize five commercially available PLA filaments which were differentiated by color, as follows: blue (1), gray (2), transparent (3), orange (4) and natural (5) comparing to a pellet pattern. Thermal characterization was performed throughout simultaneous thermogravimetry (TG), derivative thermogravimetry (DTG), differential thermal analysis (DTA) and differential scanning calorimetry (DSC). Significant differences in the enthalpies and temperatures of crystallization and melting indicated differences in crystallinity of the filaments corroborated by the XRD analysis. While analyzing using TG/DTG–DTA, significant differences in thermal stability were observed. The absorption spectroscopy in the infrared was also done to determine the chemical composition of the samples. Additionally, it was also observed the structure, size and roughness of the filaments using confocal microscopy building three-dimensional images. The oscillatory rheometer was employed to determinate the complex viscosity (\(\eta ^*\)), the store modulus (\(G'\)) and the loss modulus (\(G''\)) as a function of frequency (\(\omega\)). After conducting the characterizations, it was possible to compare the five types of PLA filaments and identify the best one to feature a functionalization in the future, which possibly enable them in tissue engineering applications. Results indicated that the blue filament fulfilled the best results regarding print quality, higher-temperature degradation and thermal stability, with the molar mass and viscosity superior to the other filaments.

Similar content being viewed by others

References

Bandyopadhyay A, Bose S, Das S. 3D printing of biomaterials. MRS Bull. 2015;40:108–15.

Ventola CL. Medical applications for 3D printing: current and projected uses. Pharm Ther. 2014;39:704–11.

Chia HN, Wu BN. Recent advances in 3D printing of biomaterials. J Biol Eng. 2015;9:1–14.

Hoque ME, Chuan YL, Pashby I. Extrusion based rapid prototyping technique: an advanced platform for tissue engineering scaffold fabrication. Biopolymers. 2012;97:83–93.

Takagaki LK. Tecnologia de impress 3D. In: Alessandro Marco Rosini, editor. Revista Inovao Tecnolgica. So Paulo; 2012. p. 28-40.

Rengier F, Mehndiratta A, von Tengg-Kobligk H, Zechmann CM, Unterhinninghofen R, Kauczor HU, Gieser FL. 3D printing based on imaging data: review of medical applications. Int J Comput Assist Radiol Surg. 2010;5:335–41.

Gross BC, Erkal JL, Lockwood SY, Chen C, Spence DM. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal Chem. 2014;86:3240–53.

Lopes SM, Jardini AL, Filho RM. Poly (lactic acid) production for tissue engineering applications. Proc Eng. 2012;42:1402–13.

Lasprilla AJ, Martinez GA, Lunelli BH, Jardini AL, Filho MR. Poly-lactic acid synthesis for application in biomedical devices—a review. Biotechnol Adv. 2012;30:321–8.

Ndazi BS, Karlsson S. Characterization of hydrolytic degradation of polylactic acid/rice hulls composites in water at different temperatures. Express Polym Lett. 2011;5:119–31.

Carrasco F, Pages P, Prez-Gmes J, Santana OO, Maspoch ML. Processing of poly(lactic acid): characterization of chemical structure, thermal stability and mechanical properties. Polym Degrad Stab. 2010;95:116–25.

Murphy CA, Collins MN. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym Compos. 2018;39:1311–20.

Coelho A. TopasAcademic Version 5. In: Coelho Software. Brisbane, Austrlia; 2007. http://www.topas-academic.net. Accessed 15 Jan 2017.

Zou H, Yi C, Wang L, Liu H, Weilin X. Thermal degradation of poly(lactic acid) measured by thermogravimetry coupled to Fourier transform infrared spectroscopy. J Therm Anal Calorim. 2009;97:929–35.

Drumond WS, Wang SH, Moth CG. Sntese e caracterizao do copo-mero poli(cido ltico-b-glicol etilnico). Polmeros Cincia e Tecnologia. 2004;14:74–9.

Chapple S, Anandjiwala R, Sinha RS. Mechanical, thermal, and fire properties of polylactide/starch blend/clay composites. J Therm Anal Calorim. 2013;113:703–12.

Gray AP. Polymer crystallinity determinations by DSC. Thermochim Acta. 1970;1:563–79.

Mathot VBF. Calorimetry and thermal analysis of polymers. New York: Hanser Publications; 1994.

Kong Y, Hay JN. The measurement of the crystallinity of polymers by DSC. Polymer. 2002;43:3873–8.

Kong Y, Hay JN. The enthalpy of fusion and degree of crystallinity of polymers as measured by DSC. Eur Polym J. 2003;39:1721–7.

Allegra G, Corradini P, Elias HG, Geil PH, Keith HD. Definitions of terms relating to crystalline polymers (Recommendations 1988). Pure Appl Chem. 1989;61:769–85.

Fischer EW, Sterzel HJ, Wegner G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reaction. Kolloid-Zu Z-Polymer. 1973;251:980–90.

Peng B, Hou H, Song F, Wu L. Synthesis of high molecular weight poly(l-lactic acid) via melt/solid state polycondensation. II. Effect of precrystallization on solid state polycondensation. Ind Eng Chem Res. 2012;51:5190–6.

Garcia PS, Scuracchio CH, Cruz SA. Effect of residual contaminants and of different types of extrusion processes on the rheological properties of the post-consumer polypropylene. Polym Test. 2013;32:1237–43.

Acknowledgements

The authors acknowledge the FAPESP for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matos, B.D.M., Rocha, V., da Silva, E.J. et al. Evaluation of commercially available polylactic acid (PLA) filaments for 3D printing applications. J Therm Anal Calorim 137, 555–562 (2019). https://doi.org/10.1007/s10973-018-7967-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7967-3